Project category

MACHINE VISION

The Challenge

Quality control.

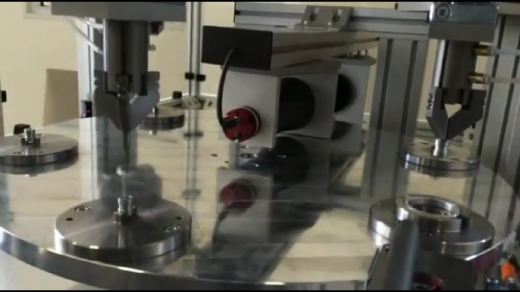

The inspection of a multilayer tube ( O16.36mm ) over 360°, during the extrusion conducted at a 50mt/min speed, is required. It is necessary to individuate aesthetical and/or geometrical flaws: dark blots, superficial clumps or dips, roughness or lack of the covering material.

The Solution

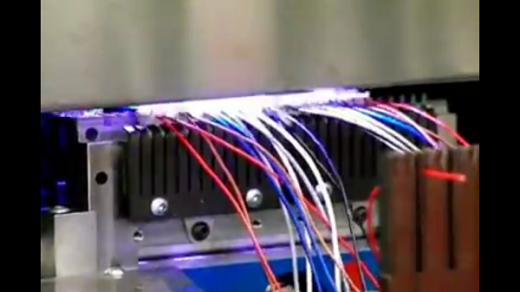

A vision system made of three cameras and a special lighting system, inspects real time the entire tube’s surface. Images are acquired and elaborated at a 500 per second speed and, in case of flaws, images are saved on disc, together with time and date, for further evaluations. The system is also able to control an automatic miter saw when available.

Installed in Italy.